Why are the teeth on car transmission gears slanted?

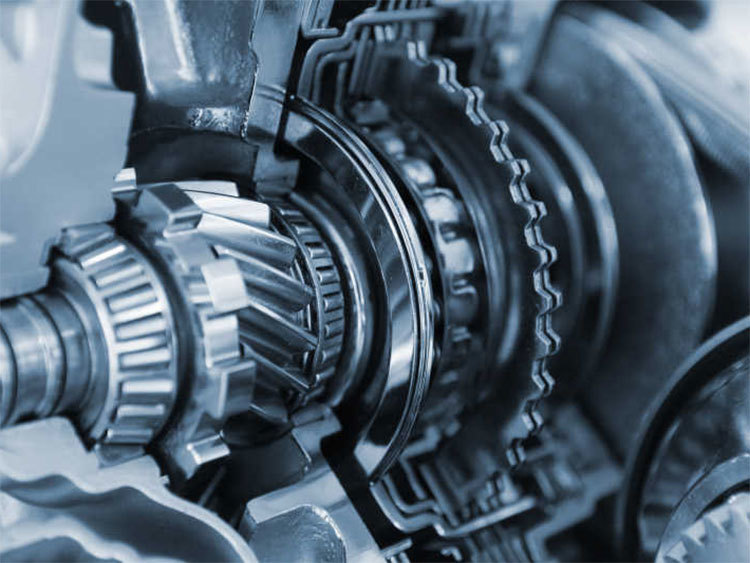

The forward gear is the most frequently used gear in a car. Using helical gears ensures sufficient strength while also being quieter and more comfortable, so car transmissions basically all use helical gears. These gears are known as helical gears, and they have a relatively larger load-bearing capacity and less noise and vibration compared to straight gears. In addition, the number of teeth and the contact area engaged at the same time during the transmission process are limited for straight gears, unlike helical gears. Moreover, to transmit a larger torque, larger teeth are needed, and when the teeth are made larger, the size of the gear increases. However, the advantage of straight gears is that they can freely engage and disengage horizontally, and many automobile...

View More →

08

/

10

2021

Common malfunctions and solutions for snail gear reducers

I. Common Problems and Their Causes Keywords: Speed reducer, Gearbox, Transmission 1. Speed reducer overheating and oil leakage. In order to improve efficiency, worm gear reducers generally use non-ferrous metals for worm gears, and harder steel for worm shafts. Due to sliding friction transmission, a lot of heat will be generated during operation, causing thermal expansion differences between the various parts and seals of the reducer, resulting in gaps in the various mating surfaces. Due to the increase in temperature, the lubricating oil becomes thinner and is prone to leakage. There are four main reasons for this situation: first, unreasonable material matching; second, poor quality of the meshing friction surface; third, insufficient lubrication oil addition

View More →

04

/

13

2018

Future prospects of powder metallurgy gears

Although the powder metallurgy industry has experienced nearly 10 years of rapid development, there are still several gaps compared with foreign counterparts: many enterprises, small scale, and significant differences in economic benefits compared with foreign enterprises. Product overlap, enterprises undercutting each other, and fierce competition. Backward technology and supporting facilities. Few product exports and poor trade channels. After China's accession to the WTO, the above-mentioned shortcomings and weaknesses will be improved, because after joining the WTO, the market will gradually become internationalized, and the powder metallurgy market will have further opportunities for expansion; at the same time, with the inflow of foreign funds and technology, powder metallurgy and related technical levels will inevitably improve.

View More →

04

/

13

2018

Current Status of Powder Metallurgy

Powder metallurgy is a process technology for producing metal or using metal powder (or a mixture of metal powder and non-metal powder) as raw materials, which are formed and sintered to produce metal materials, composites, and various types of products. Powder metallurgy has similarities with ceramic production, therefore a series of new powder metallurgy technologies can also be used for the preparation of ceramic materials. Due to the advantages of powder metallurgy technology, it has become the key to solving new material problems and plays a pivotal role in the development of new materials. China's powder metallurgy industry has experienced nearly 10 years of rapid development, but there are still several gaps compared with foreign counterparts

View More →

04

/

13

2018

Recently passed acceptance in Nanchang, presided over by the Jiangxi Provincial Department of Science and Technology. The successful development of this project has laid a solid theoretical and experimental foundation for promoting the progress of injection molding technology in China and improving the gas-assisted injection molding process for plastic product enterprises. Experts believe that this project has pioneered relatively mature theoretical and experimental research on gas-assisted injection molding at home and abroad, establishing a mathematical model of the gas-assisted injection molding filling process for three-dimensional thin-walled parts. The independently developed gas-assisted injection molding injection control system software based on the Windows platform is highly practical and can simulate the injection molding process to identify molding process defects in advance. At the same time

View More →

04

/

13

2018

Chongqing Winstar Precise Machinery Co., Ltd. was established in September 1999. In December 2004, it separated from Chongqing Qingshan Industrial Co., Ltd. and transformed from a state-owned enterprise to an employee collective shareholding company. The company specializes in the production of automotive planetary gears, axial gears, and synchronizers. It stably supplies parts to Changan, Huachen, BAIC, Geely, Haima, Changhe Automobile, as well as SAIC-GM-Wuling, FAW Group, and Yu'an Xiaokang, which are equipped with gearboxes and new energy reducers from Qingshan, Wanliyang, Beijing Precision, Zhongma, Huachen, OGR, and Dong'an. The company has been awarded the title of "Technical Center" and "High-tech Enterprise" at the Chongqing municipal level.

View More →

04

/

13

2018